© IEP

Implementation: How is the research organized?

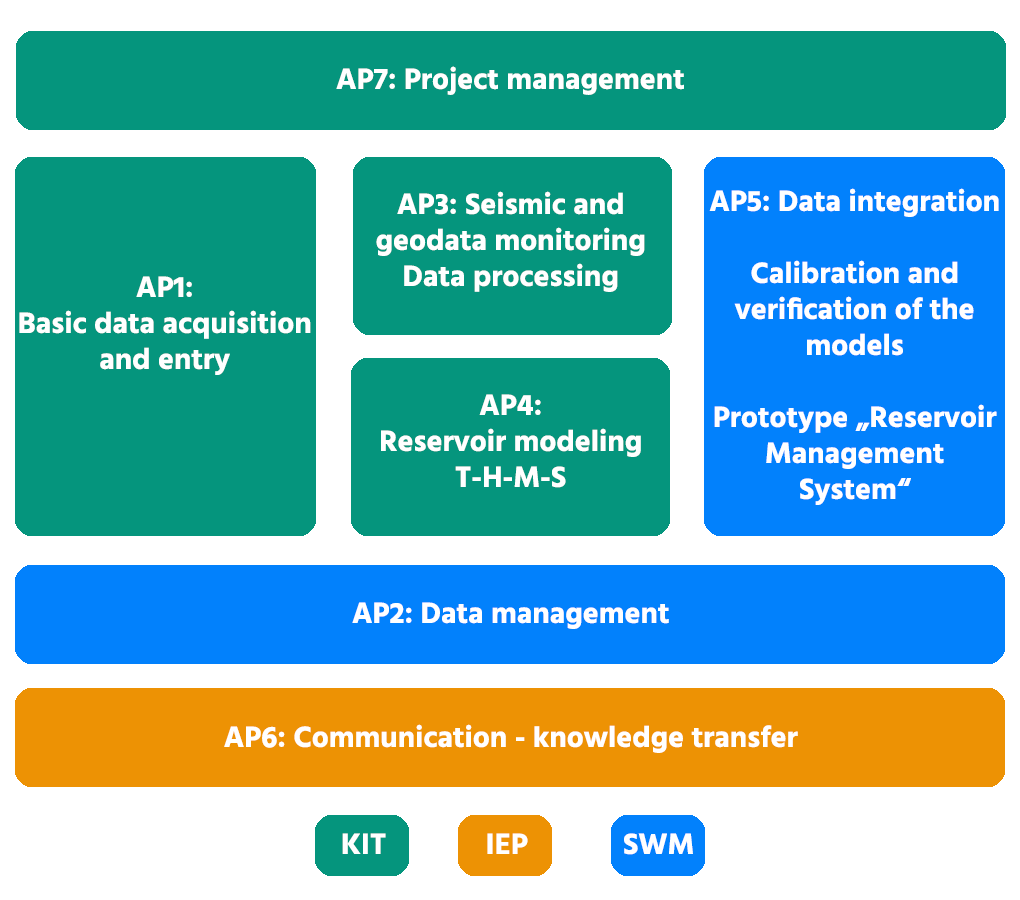

The INSIDE project is a way for IEP, SWM and KIT to address questions regarding induced seismicity and ground deformation near geothermal boreholes. The main focus is on measuring and studying coupled thermal-hydraulic-mechanical processes representing the reservoir and its environs – i.e. the bedrock and overlying rock. Operational processes are put into context with detectable seismic events and the planned scientific investigations will provide the basis for integrating the findings into operations. This will form the technical foundation for handling, evaluating and monitoring the measured data while numerical models will be used to predict fluid-induced seismicity and/or ground deformation.

The work packages are defined as follows:

1) Expansion of a measurement concept and a measurement network that go beyond the standard (state of the art) for collecting data on

- geological and geophysical parameters from the reservoir and the overlying rock

- active and passive acoustics with an innovative measurement methodology not yet used in geothermal energy (mini array, fiber optic cable)

- possible ground deformations at the surface (uplift or subsidence)

The focus is on an approach that incorporates a variety of instrumentation, configurations and locations when monitoring seismicity and ground uplifting/subsidence.

2) Creation of a data management system for the above monitoring concept – with capacity for further expansion. This needs to be able to handle large amounts of data and different levels of access.

3) Interpretation and comparison of measurements from the monitoring network – i.e. mutual performance comparisons (benchmark) of the implemented instrumentation and measurement configurations with respect to their suitability for monitoring seismicity and ground uplifting/subsidence.

4) Development of an improved conceptual model through coupled thermal-hydraulic-mechanical modeling using the acquired data. This will include the development of innovative numerical modeling approaches that lead to the elaboration of calibrated site models and that can subsequently be used to predict induced geological-geophysical processes in the subsurface.

5) Establishment of a monitoring system for integrating all acquired data from the work packages mentioned above.

6) Development of a communication strategy involving communications experts for the public and geoscientists.

Highlights

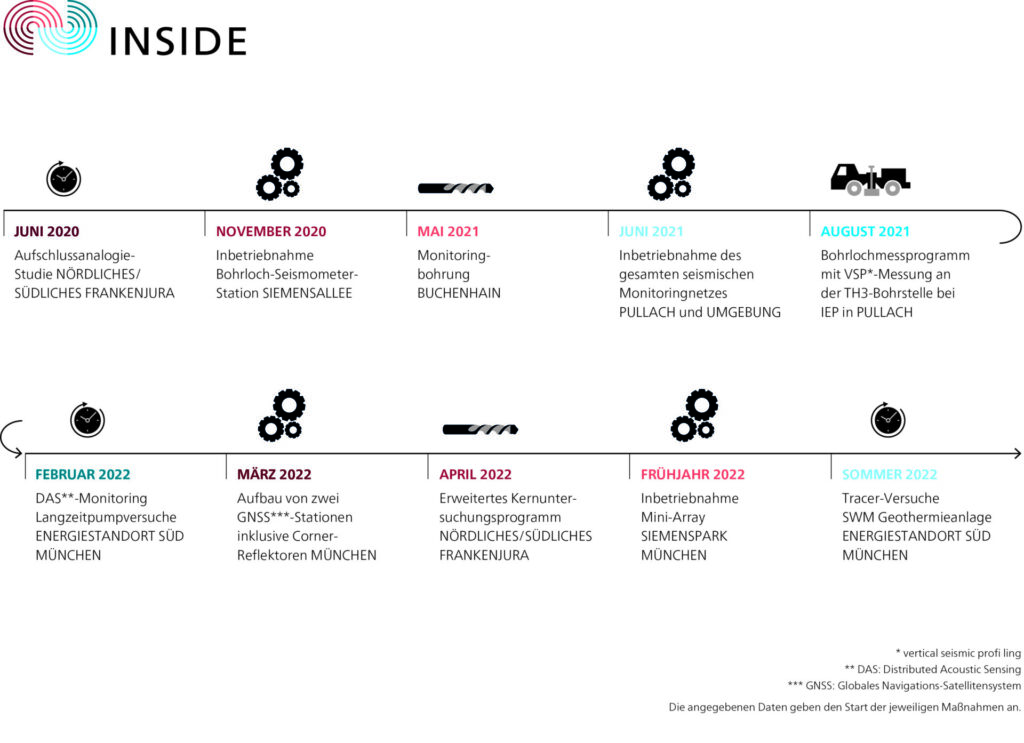

30 June 2020

Seismic monitoring is a key aspect of the INSIDE project. One of the goals is to develop a seismic network for continuous recording and real-time monitoring of microseismicity. Existing seismic monitoring stations in the region will be shared in order to create a network with short distances between stations. This will allow the detection of low magnitude events that would otherwise be unrecordable.

The INSIDE monitoring network will establish seismic stations at a total of five locations (Sendling/Schäftlarnstraße, Pullach and Baierbrunn).

Preparations: noise measurements (26-28 May 2020).

Anthropogenic background noise and invisible noise sources can have a strong impact on the quality of microseismicity recording and interpretation.

In order to assess those noise levels, field measurements were made at various sites and are currently ongoing. The goal of the measurement is to quantify the seismicity detection capability for each planned site.

For each site tested, the procedure was as follows:

- a trench was excavated (approximately 80 cm long, 50 cm wide and 50 cm deep).

- the measurement instruments were left in the backfilled trench for approximately 24 to 48 hours

- the gauges were then recovered and the trench was backfilled

- the recorded waveforms were analyzed to evaluate noise levels.

The measuring instruments used were:

- Lennartz LE3D Lite seismometer, 1 Hz, 800 V/m/s, 3-component

- DATA CUBE³ data logger

- Battery, junction box, GPS antenna

The measurements of the background noise, which took place between May 26 and May 28, 2020, allowed the validation of the tested positions.

Buchenhain monitoring borehole

In progress. Coming soon!

2 October 2020

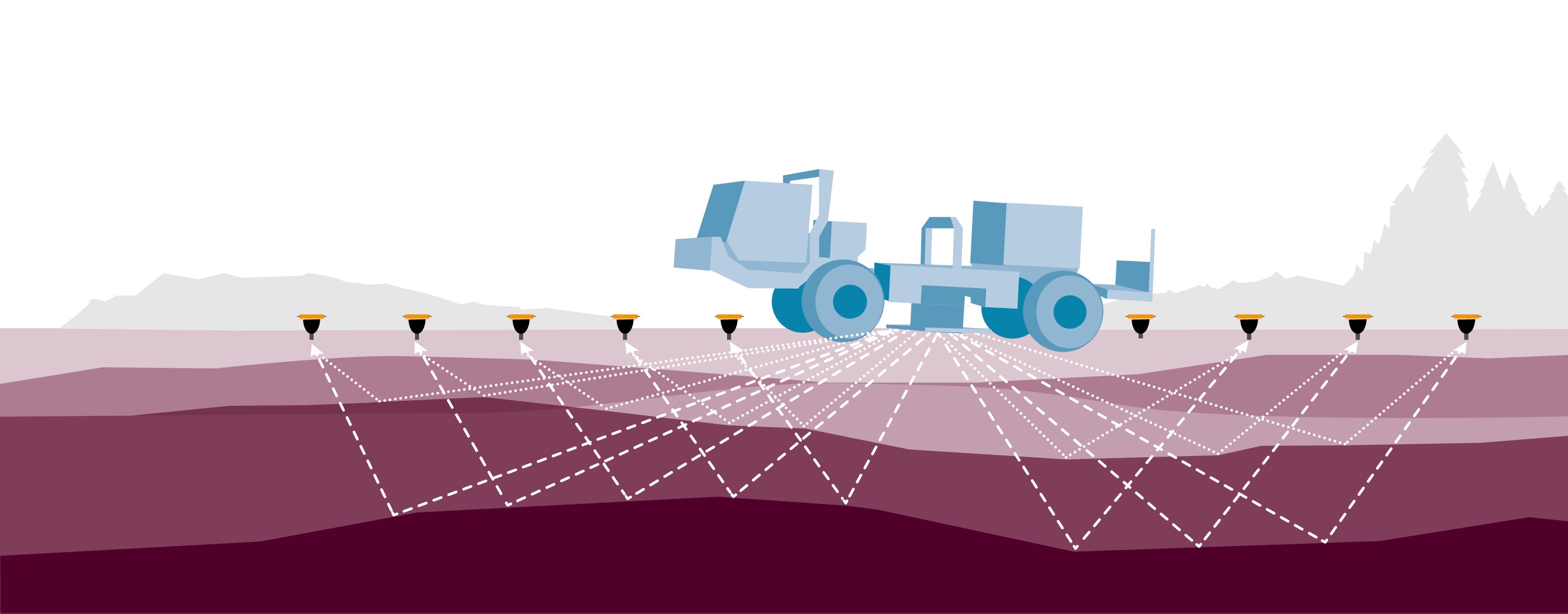

SWM is breaking new ground in the geothermal scene with the sparker measurements, which will take place after drilling work is completed and before the new geothermal plant in Schäftlarnstraße in Munich is put into operation. The experiment is designed to use rock parameters to determine velocities and layer structures, which in turn help find the hypocenter of seismic events. To do this, the propagation velocity of seismic (acoustic) waves is required, in particular, and a team of national and international experts is supervising the measurements both technically and scientifically.

SWM intends to use the results of the sparker measurements to derive valuable findings for the operational safety of Germany’s largest geothermal plant to date as well as for other future plants. Surface seismometers and fiber optic measurement tools will be used to test the recording of small vibrations and determine their sensitivity.

The technique was originally developed for the oil and gas industry, but the procedure and execution will be adapted to the general conditions of geothermal energy (Figures 2 and 3 on the website). During the measurement, an acoustic wave is excited deep underground. The aim is to localize vibrations as accurately as possible that may occur in the reservoir due to geomechanical and microseismic processes.

The Avalon Sciences Ltd. sparker used in the procedure is a high-voltage source. It charges electric voltage at an electrode up to a maximum of 5 kJ, discharges it again at a capacitor and excites acoustic waves with a released energy of about 1 kJ (link to video from Avalon and data sheet Fig. 2, bottom right). The amount of energy of 1 kJ is very small compared to acoustic waves excited on the surface (for example, 10 times the energy is excited with an accelerated drop weight, 200 times with a large vibrator). The measurement period is planned over four days, with multiple acoustic excitations at different depths using the source.

Fiber optic cables are a promising advantage for the sparker measurements. They are comparable to the fiber optic cables used for telecommunications. Such measuring devices have already been installed by TUM/ Geothermal Alliance Bavaria in two of the total of six boreholes in Schäftlarnstraße. They are used to record high-resolution acoustic signals in addition to temperature and pressure data. Initial evaluations of the Distributed Acoustic Sensing (DAS) measurements, which took place in early April 2020 during a Vertical Seismic Profiling (VSP) measurement campaign, show that acoustic waves excited from the surface can also be recorded in the subsurface.

15 December 2020

Two measuring stations are to be installed in the first half of 2021: one on the operating site of the Th3 borehole in Pullach and one on the open-air site of the Maria-Einsiedel-Bad near the landing point of the Th6 borehole of the Schäftlarnstraße geothermal project. Suitable locations are still being sought for two further stations.

Radar satellite data processing based on the SAR interferometry (InSAR) method has already begun. A combination of C-band and X-band radar scenes will be processed to achieve a dense sampling of the deformation field. ESA’s Sentinel-1 mission provides the C-band data, while the higher-resolution X-band images come from the TerraSAR-X satellite mission of the German Aerospace Center (DLR). The data sets contain radar images from ascending and descending orbits, allowing the vertical and horizontal components of the 3-dimensional deformation vector to be separated. One scene with identical imaging geometry is recorded for each orbit every 11 days (TerraSAR-X) or every 12 days (Sentinel-1).

Currently the data set consisting of 150 images of the descending (i.e. north-to-south) orbit No. 168 (October 2014 to April 2020) is being processed using the persistent scatterer technique (“PS-InSAR”). In order to increase the number of radar back-scatterers (data points) that can be used for deformation measurements in the area of interest, the initial PS method used will be combined with the distributed scatterer technique (DS), which will help locate non-point back-scatterers.

Due to the shorter wavelength of the X-band radar signals we can expect an increased number of measurement points in urban areas from the TerraSAR-X data set. This data is processed separately and the results are combined with those from the C-band data set to ensure the highest possible density of analyzed measurement points. The analyzed TerraSAR-X data is currently being collected by DLR.

In progress

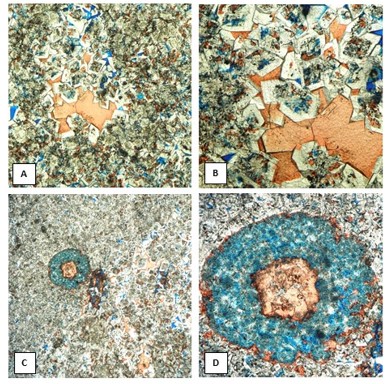

Based on the support of Prof. Dr. Roman Koch from the University of Erlangen (FAU), different intervals of the Malm sequence were gathered in June 2020 from analog outcrops within the Northern and Southern Franconian Jura.

Since these rocks have similar properties to the rocks drilled in geothermal wells in the Munich area, knowledge about the Malm reservoir underground can be investigated. An extensive measurement program was carried out on a total of 30 drilled cores, in which the Ruhr University Bochum (RUB) was involved.

The objective of the sampling and measurements was to determine the petrophysical parameters of the reservoir, which are used as input parameters for geomechanical models.

dolomite rocks at the Kindinger Stege

The following were measured:

- P- und S-wave velocities ((P-waves are similar to ultrasonic waves in air, S-waves to transverse movement of light waves and are therefore also called shear waves)

- Determination of the triaxial compressive strength and the modulus of elasticity (proportional relationship between stress and strain during deformation of the rock) as well as evaluations according to Mohr-Coulomb and Hoek-Brown (both evaluations to determine the fracture criteria of rocks)

- Indirect determination of tensile strength by cleavage test

- Determination of the bulk density using a pycnometer, including determination of the total porosity (Relative density – Wikipedia)

- Determination of the permeability in the Darcy test (characterizing the permeability of a porous material), including determination of the effective porosity by drying and saturating.

- Determination of the bulk density using a pycnometer, including determination of the total porosity

- Ultrasonic measurements between the trixial pressure levels on 20 drill cores by the RUB

- Execution and analysis of additional thin sections on the samples examined in the RUB rock laboratory to determine the mineral composition

In April 2022, another 15 analogue samples were collected to expand the database. For these samples, the measurement program is expanded to include e.g. the temperature-expansion coefficient, which is intended to provide additional insights into the effect of rock cooling in the area of the injection wells.

In progress

Results

Mission accomplished!

As planned, the dedicated vertical monitoring well has been drilled at Buchenhain, until 250 m depth and two fibre optic cables have been cemented in. Both cables will be used for Distributed Fibre Optic Sensing, a data acquisition approach enabling to turn fibre optic cables into a line of distributed sensors recording specific physical parameters, once they are connected to the associated processing machine. One cable is dedicated to Distributed Acoustic Sensing (DAS) and the other one to Distributed Temperature and Strain Sensing (DTSS). In addition to the vertical deployment, fibre optic cables have been buried at 80 cm below surface to form a ca. 100-m loop. All the associated recording devices are stored on the surface in a ventilated and insulated electrical closet (Figure 1). With this set-up and the continuously acquired data, we expect to observe potential seismicity and ground deformation in the vertical and horizontal directions. Next to the fibre-optic based sensors a standard long-period three-component seismometer is installed in a shaft (Figure 1). Hence, the responses and sensitivities of all sensors can be compared. This makes the Buchenhain seismic station very peculiar and of great value.

We warmly thank the personnel of the companies Baugrund Süd, Pfaffinger and Febus Optics for their work on site. We also thank the neighbours of the Lindenstraße monitoring site for their patience during the installation work.

Monitoring the long-term pump-tests at the Schäftlarnstraße geothermal site using Distributed Acoustic Sensing (DAS)

The Schäftlarnstraße geothermal field (Sendling) is one of the project sites under focus. Two fibre optic cables have been deployed at this location thanks to the Technical University of Munich (TUM)/Geothermal Alliance of Bavaria (GAB) and SWM: one cemented behind the casing of the injection well Th3, over 700 m, and the other one in the production well Th4, which is coupled to a sucker rod deployed in the well until final depth. Hence, Distributed Acoustic Sensing (DAS) acquisition and processing are possible along the associated optical fibres.

Since February 2022 and until end of July 2022, a DAS interrogator is connected to the Th3 fibre-optic cable and is recording continuously. The objective is to study the ground vibrations and the seismogenic response of the subsurface that could be generated during the long-term geothermal fluid circulation tests, which is carried out at the site during this period.

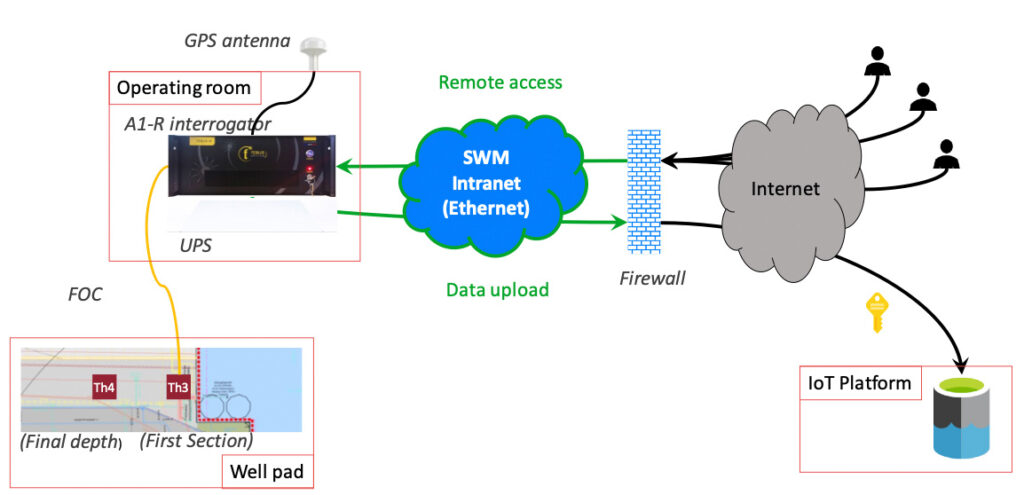

As DAS acquisitions generate a tremendous amount of data, ~5 TB/month, a data-management infrastructure has been developed for the storage and for the analysis of the recordings. An Internet-of-Things (IoT) platform has been developed for that purpose. It is connected to the DAS interrogator via the SWM network and offers a cloud-based data processing and storage solution. As illustrated Figure 1, the proposed set-up enables storing the data in real-time on the IoT platform. It also provides a secure access to the data and to the recorder.

In order to detect possible seismic events from the subsurface, KIT implemented automatic DAS data processing on the cloud platform, benefiting from scalable computing capabilities. Hence, on an hourly-basis, DAS strain-rate data are reshaped and converted. Then, dedicated seismological processing is carried out to extract seismic event candidates that are manually reviewed. About 10 minutes of processing are required to analyse 1 hour of DAS strain-rate data.

So far, the infrastructure that has been implemented looks very suitable and efficient for our purposes, and its implementation to other geothermal sites should be feasible. Hence, it could be seen as the backbone component of a future reservoir management system.

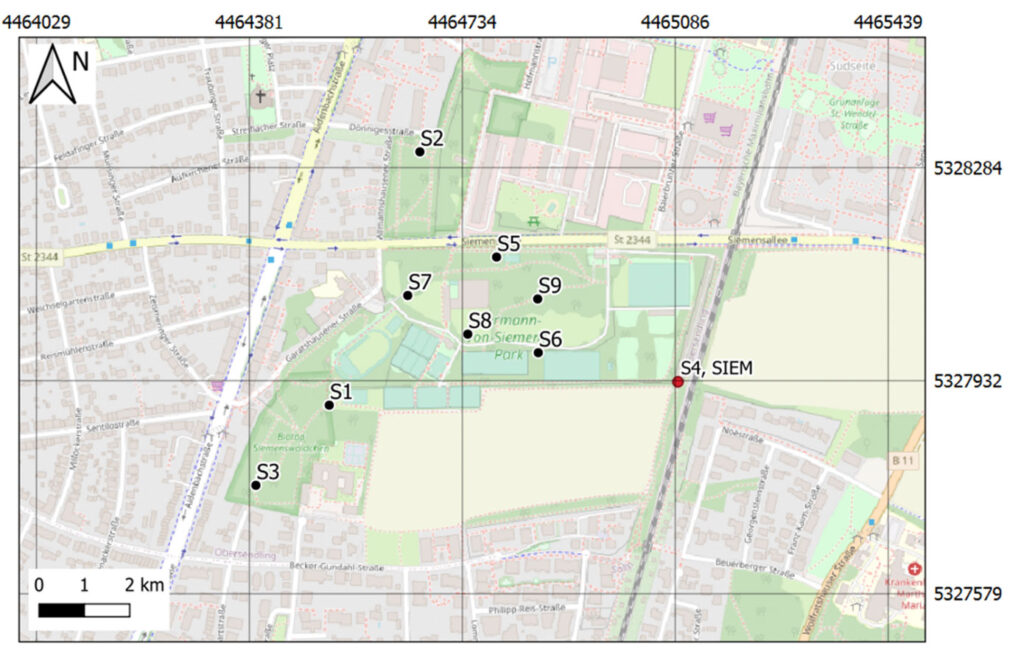

Since 11/05/2022, a mini-array is recording seismic vibrations in the Siemenspark (Munich). It consists of a system of stations arranged in a specific geometric pattern that should increase the detection sensitivity of seismic event thanks to specific data analysis based on array processing technics. The scientific objective is to assess whether such a mini-array performs better than a standard seismic station or a borehole station in identifying underground weak seismicity, especially in an urban noisy environment.

After obtaining the permits from the City of Munich, the nine seismic stations, which are forming three branches of three stations each, were installed and started acquiring data continuously (Figure 1). The sensitivity of the mini-array will be evaluated with respect to the detection capabilities of the borehole station ‘SIEM’, installed in a nearby well at a depth of 170 m, under surface (Figure 1).

The seismic stations constituting the mini-array are working autonomously. Each of them is buried in a 50 x 50 x 50 cm³ hole and is composed of a three-component seismometer, a data logger, a GPS antenna and a battery (Figure 2). Data are stored locally and will be retrieved periodically. The monitoring should last until the end of the project.